This website uses cookies to manage authentication, navigation, and other functions. By using our website, you agree that we can place these types of cookies on your device.

You have declined cookies. This decision can be reversed.

You have allowed cookies to be placed on your computer. This decision can be reversed.

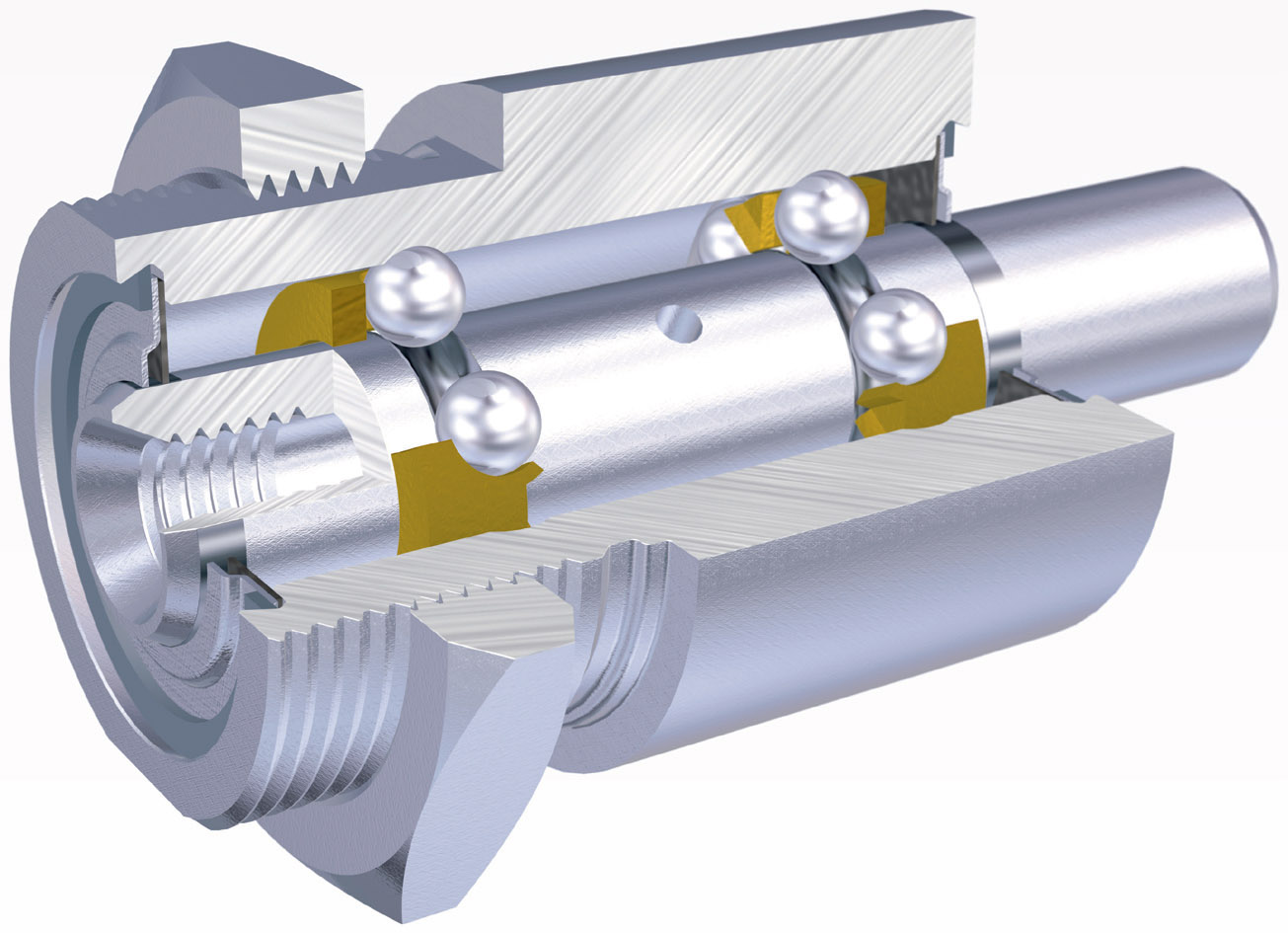

Special double-row ball bearings for textile machines and measurement instruments built not separable unit, which consists of cylindrical bushing and shaft, arranged in two rows of balls. The balls are led in light one-sided cages. The raceways on the shaft and in cylindrical bushing are made in high accuracy degree. Effective contact or non-contact seals on both sides of bearings prevent penetration of impurities. The bearings are filled with a grease of high quality providing constant lubrication during their whole life. In some cases the design of the bushings makes possible relubrication during a bearings life.

A special double-row ball bearing creates a complete bearing unit which enables simple assembly and maintenance. The development of these bearing hangs together with a solution of arrangements of the most important parts in the textile machines but also for measuring instruments.

Special double-row ball bearing for textile machines are designed for high rotational speed and relatively light load. They are known for they high dimensional accuracy and smooth run warranting their high effectiveness.

| Bearing designation | D | d | L | Limiting speed |

|---|---|---|---|---|

| mm | min-1 | |||

| 73-1-13 | 22 | 10 | 92 | 35000 |

| 73-1-14 | 22 | 10 | 112 | 55000 |

| 73-1-14B | 22 | 10 | 112 | 55000 |

| 73-1-20 | 22 | 10 | 112 | 35000 |

| 73-1-22 | 22 | 10 | 112 | 55000 |

| 73-1-22B | 22 | 10 | 112 | 55000 |

| 73-8 | 22 | 12 | 111 | 65000 |

| 73-1-24 | 22 | 10 | 112 | 70000 |

| 73-1-31 | 22 | 10 | 112 | 75000 |

| 72-6 | 22 | 9 | 112 | 85000 |

| 72-6B | 22 | 9 | 112 | 75000 |

| 72-10 | 22 | 9 | 112 | 90000 |

| T010 | 22 | 9 | 112 | 100000 |

| T011 | 22 | 9 | 112 | 100000 |

| T013 | 22 | 9 | 108 | 100000 |

| T001 | 22 | 9 | 112 | 85000 |

| T081 | 22 | 10 | 112 | 75000 |

| 73-1-35 | 34 | 10 | 110 | 25000 |

| 73-1-64 | 34 | 10 | 136 | 60000 |

| 74-4-1 | 34 | 12 | 112 | 30000 |

| 74-5-4 | 34 | 12 | 110 | 30000 |

| 76-3 | 30 | 16 | 73 | 10000 |

| 76-3KK | 30 | 16 | 73 | 10000 |

| 76-3-7 | 30 | 16 | 73 | 10000 |

| 76-3-7KK | 30 | 16 | 73 | 10000 |

| 76-3-1 | 30 | 16 | 96 | 12000 |

| T 763 | 30 | 16 | 73 | 10000 |

| 73-1-36 | 22 | 10 | 95 | 15000 |

| 73-1-40 | 24 | 10 | 65 | 15000 |

| 73-1-43 | 24 | 10 | 65 | 15000 |

| 73-7-11 | 25 | 11 | 98 | 15000 |

| 74-10 | 33 | 14 | 91.8 | 22000 |

| 74-10-1/76 | 28 | 14 | 228 | 22000 |

| 74-10-1/77 | 28 | 14 | 199 | 22000 |

| 74-10-1/78 | 28 | 14 | 206 | 22000 |

| 74-10-1/79 | 28 | 14 | 177 | 22000 |

| 74-10-2 | 30 | 14 | 101 | 22000 |

| 74-10-7 | 30 | 14 | 94.4 | 10000 |

| 73-1-28 | 28 | 10 | 50.5 | 15000 |

| 73-1-49 | 28 | 10 | 54.5 | 15000 |

| 76-2-1 | 30 | 16 | 36 | 15000 |

| 76-2-2 | 30 | 16 | 38.2 | 15000 |

| 76-2-3 | 30 | 16 | 38.2 | 15000 |

| 76-2-7 | 30 | 16 | 49.5 | 15000 |

| 76-2-8 | 30 | 16 | 49.5 | 15000 |

| 74-8-2 | 26 | 12 | 85.5 | 18000 |

| 73-7-3 | 22 | 11 | 33.5 | 20000 |

| 73-7-4 | 22 | 11 | 33.5 | 8000 |

| 73-7-5 | 24 | 12 | 48.5 | 7500 |

| 83-15 | 38 | 22 | 70 | 80000 |

| 83-18-2 | 38 | 22 | 69 | 90000 |

| 83-18-4 | 38 | 22 | 69 | 90000 |

| 83-18-5 | 38 | 22 | 69 | 105000 |

| 83-18-6 | 38 | 22 | 69 | 115000 |

| 83-23-1 | 38 | 22 | 69 | 100000 |