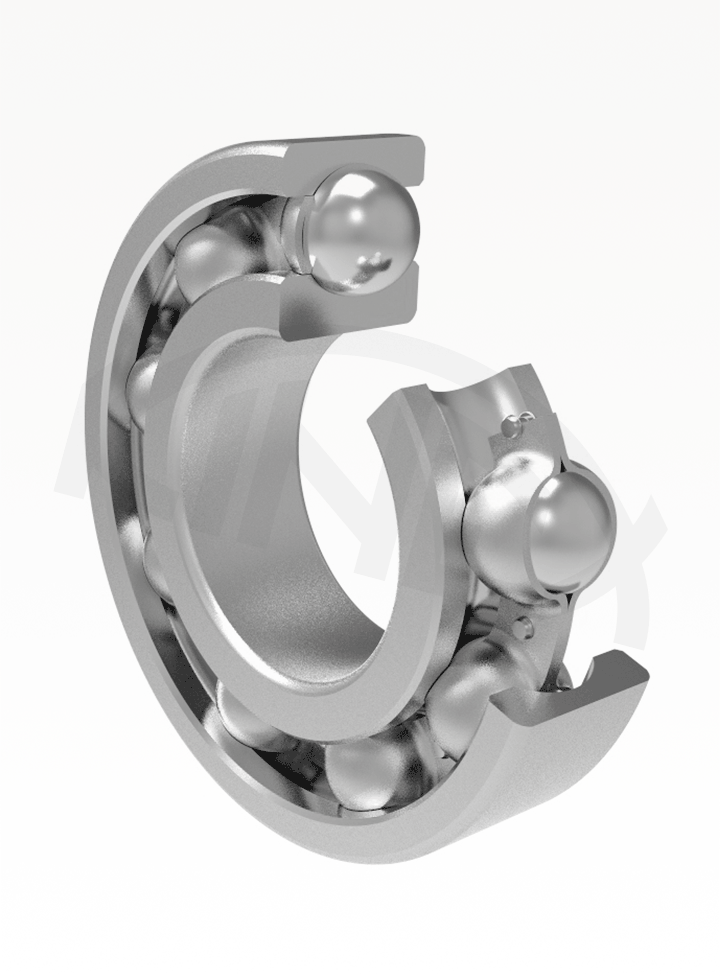

The single row deep groove ball bearings have relatively deep raceways on both rings without a filling slot and are non-separable. High load ratings are achieved by optimum ball sizes and by their conformity to the raceways. They can carry axial and radial loads in both directions and are suitable even for high rotational speeds. These bearings are manufactured in a broad assortment and are the most common rolling bearing type.

The table section are processed basic bearing parameters for the following subgroups:

• Miniature Bearings

• Thin walled Bearings 618 and 619 Series

• Standard assortment 160, 60, 62, 63 and 64 Series

The single row deep groove ball bearings with sealing on one or on both sides are manufactured with metallic shields (Z, -2Z or ZR, -2ZR) or with seals (RS, -2RS or RSR, -2RSR). Bearings with shields have a non-contact sealing. The bearings are manufactured in the original design with steps for shields on the inner ring (Z, -2Z) or, in the new design, with a shield and a smooth rib on the inner ring (ZR, -2ZR).

The sealing rings made of rubber, vulcanized on metallic reinforced rings, provide an effective friction type seal. The bearings are manufactured in the design with rounded steps on the inner ring (RS, 2RS) or, in a new design, with a seal and a smooth rib on the inner ring (RSR, -2RSR).

Bearings with seals can be used within the temperature range from -30°C to 110°C. Supplies of bearings with seals within the operating temperature range from -60°C to 180°C (RS2, 2RS2) should be negotiated with the supplier in advance. Shields and seals are firmly fixed in the groove of the outer ring and these are not removable.

Bearings with sealings on both sides (-2Z, -2RS or -2ZR, -2RSR) are filled with a quality grease the properties of which usually ensure the lubrication during the whole bearing life under normal operating conditions. The bearings of this design cannot be relubricated and can be used within the operating temperature range from -30°C to 100°C. The supply of bearings with a different grease should be negotiated with the supplier in advance.

For bearings sealed on both sides, the designation of the grease filling different from standard grease is indicated by a symbol combination the first two letters of which indicate the operating temperature range (a symbol in accordance with STN 02 4608) and the third symbol identifies the grease name.

TL - Grease for low operating temperatures (from -60°C up to 100°C)

TM - Grease for medium operating temperatures (from -30°C up to 110°C)

TH - Grease for high operating temperatures (from -30°C up to 200°C)

TW - Grease for low and high operating temperatures (from -40°C up to 150°C)

Note: The symbols of greases for medium operating temeperatures need not be marked on the bearings.

For some less demanding applications, e. g. in agricultural machines, etc., some sizes of single row deep groove ball bearings of type 62 and 63 with a tapered bore (K), taper 1:12, are manufactured. These bearings are also manufactured in a design with shields on both sides. The bearings are fixed on the cylindrical shaft by means of adapter sleeves of types H2, H3 or directly on the tapered shaft.

The single row deep groove ball bearings of the basic design are equipped with a pressed cage made of steel sheet, guided on balls, which is not designated.

These bearings are produced with different types of cages for special applications. Namely, bearings with a solid polyamide cage (TNH, TNGH) and a machined brass cage (M). The supply of these bearings should be negotiated in advance.

The limiting values of the dimensional and running accuracy deviation correspond to ISO 492. An exception is made only for the Single row deep groove ball bearings are commonly manufactured within the tolerance class P0 and P6. For special applications requiring high accuracy or for applications with a high rotational speed, the bearings in the higher tolerance classes P6, P5 and P4 are used. The bearings in higher tolerance class P6E are used for rotating electric machines.

The limiting values of the dimensional and runing accuracy deviation correspond to ISO 492. An exception is made only for the separable single row ball bearings of types E or B0 the outer diameter D of which has the limiting deviation +0.01/0.00 mm.

The bearings in the tolerance classes P5 and P4 are made of higher quality materials such as electroslag or vacuum remelted bearing steels.

The commonly manufactured single row deep groove ball bearings have a normal radial clearance which is not indicated. For special arrangements the bearings with a reduced radial clearance (C2) or with an increased radial clearance (C3, C4, C5) are supplied.

The currently manufactured single row deep groove ball bearings have a normal vibration level determined by the manufacturer. For special applications with high requirements on noisless operation, bearings with reduced vibration level are supplied (C6).

The symbols for the tolerance classes, bearing internal clearances and vibration levels are combined with the simultaneous omission of the symbol C in the second and the following bearing special characteristics, e. g.:

P6 + C3 = P63 6004 P63

C3 + P6 = C36 6303-2RS C36

P6 + C3 + C6 = P636 6204-2Z P636

For arrangements with a higher operating temperature than 120°C, special heat treated-stabilised-single row deep groove ball bearings are supplied the form stability of which at operating temperature 150°C up to 400°C (S0, S1, S2, S3, S4, S5) is ensured.

The supply of stabilised bearings should be negotiated with the supplier in advance.

For single row deep groove ball bearings only small mutual misalignment of bearing rings is permissible, therefore alignment deviation of seating surfaces can be very small. Misalignment causes additional loading of the bearing and thus its life is shortened.

Values of permissible misalignment at normal operating conditions are shown in the table.

Bearing type Load

light (Fr<0,15 Cor) heavy (Fr ≥ 0.15 Cor)

618,619,160,60 2′ to 6′ 5′ to 10′

62,63,64 5′ to 10′ 8′ to 16′

Pr = Fr for Fa/Fr ≤ e

Pr = 0,56 Fr + YFa for Fa/Fr > e

Coeficients

Fa/Cor e Y

0.025 0.22 2

0.040 0.24 1.8

0.070 0.27 1.6

0.130 0.31 1.4

0.250 0.37 1.2

0.500 0.44 1

Por = 0,6 Fr + 0,5 Fa (Por ≥ Fr)

The bearing designation in the basic or current modified design is indicated in the dimension tables. The modification of the basic design is designated by additional symbols (prefixes and suffixes) in accordance with STN 02 4608. The meaning of the most frequently used symbols for the single row deep groove ball bearings is indicated in the table.

| Symbol | Example of designation | Meaning |

| X | X 625P5 | Stainless steel |

| RS | 6002 RS | Single seal |

| -2RS | 6300-2RS | Double seal |

| RSR | 6210 RSR | Seal on one side adhering to flat rib surface of inner ring |

| -2RSR | 6210-2RSR | Seals on both sides adhering to flat rib surface of inner ring |

| Z | 6317 Z | Metallic shield on one side |

| ZN | 6204 ZN | Metallic shield on one side and snap ring groove on the opposite side |

| -2Z | 6308-2Z | Metallic shields on both sides |

| -2ZR | 6005-2ZR | Metallic shields on both sides resting on the flat rib of inner ring |

| K | 6204-2ZK | Tapered bore with taper 1:12 |

| N | 6416 N | Snap ring groove in outer ring |

| NR | 6310 NR | Snap ring groove in outer ring and inserted snap ring |

| Y | X 623 Y P5 | Pressed brass cage, rolling element centered |

| TNH | 6002 TNH | Balls guided plastic cage |

| M | 6319 M | Solid brass cage guided on balls |

| MA | 6209 MA | Solid brass cage guided on outer ring |

| TB | 6308 TB | Solid cage made of textite, guided on inner ring |

| P6 | 6303 P6 | Tolerance class higher than normal |

| P6E | 6204-2Z P6E | Higher tolerance class for rotating electric machines |

| P5 | 6208 P5 | Tolerance class higher than P6 |

| P4 | 6007 P4 | Tolerance class higher than P5 |

| C2 | 6003 C2 | Radial clearance smaller than normal |

| C3 | 6302-2ZR C3 | Radial clearance greater than normal |

| C4 | 6005-2RS C4 | Radial clearance greater than C3 |

| C5 | 6303-2ZR C5 | Radial clearance greater than C4 |

| C6 | 6300 C6 | Reduced vibration level |

| R... | 6210 R10-20 | Radial clearance in non-standardized range (range in µm) |

| S0 | 6204 S0 | Stabilization for operation at temperature up to 150°C |

| S1 | 6301 S1 | Stabilization for operation at temperature up to 200°C |

| S2 | 6303-2ZR C5S2 | Stabilization for operation at temperature up to 250°C |

| S3 | 6303-2ZR C5S3 | Stabilization for operation at temperature up to 300°C |

| S4 | 6306-2ZR C5S4 | Stabilization for operation at temperature up to 350°C |

| S5 | 6306-2ZR C5S5 | Stabilization for operation at temperature up to 400°C |

| TPF | 6204-2Z P6E TPF | Bearings manufactured according to special technical terms agreed upon with the customer |