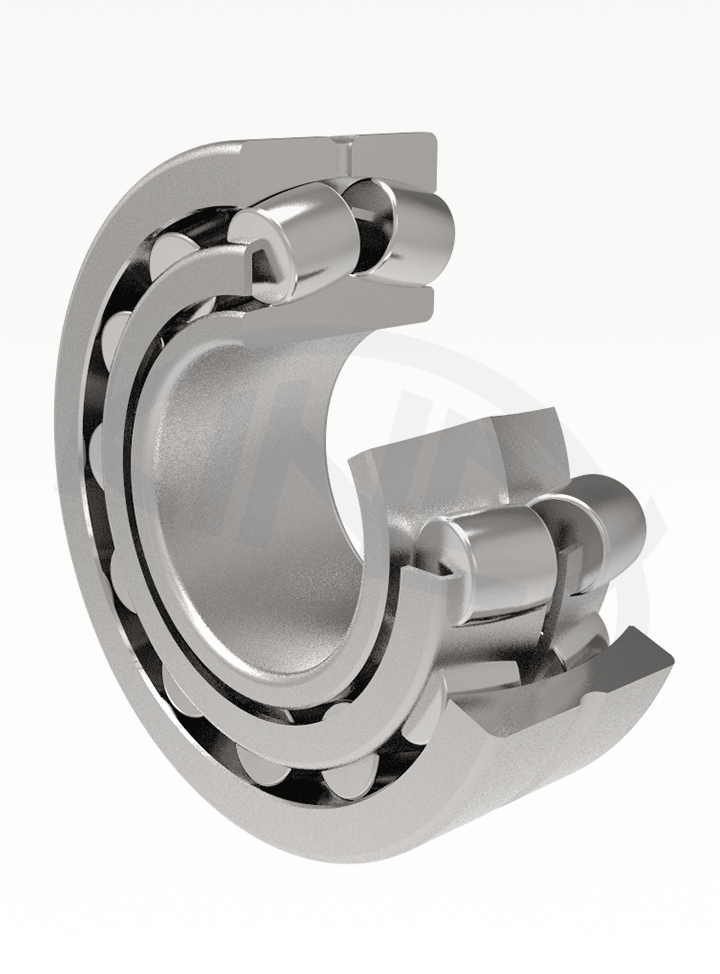

Double-row spherical roller bearings are capable of capturing heavy radial load with simultaneous axial load in both directions. Large number of long, symmetrical barrels of a large diameter arranged in two rows with a common spherical raceway on the outer ring are typical for these bearings.

The spherical shape of the raceway on the outer ring permits angular misalignment of the rings during operation and thus ensures even distribution of load on the rolling elements even with small shaft tilt or axial misalignment of the ring surfaces.

These unique parameters help spherical roller bearings achieving:

The boundary dimensions of double-row spherical-roller bearings are specified in the dimension tables and they correspond to the international ISO 15 dimension requirements.

The designation of bearings in the basic design is indicated in the dimension tables. The difference from the basic design is indicated by additional symbols.

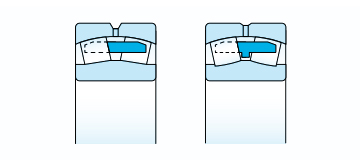

Double-row spherical roller bearings are produced with a cylindrical or tapered bore – tapering 1:12 is indicated by the symbol “K”.

Tapering 1:30 indicated by the symbol “K30” is available for the 240 and 241 series. Bearings with a tapered bore are mounted directly on a tapered shaft or on a cylindrical shaft using fastening or tightening sleeves in accordance with ISO 113 and ISO 2982-1,2.

Designation of adapter sleeve or withdrawal sleeve belonging to individual bearings with tapered hole are stated in dimension tables.

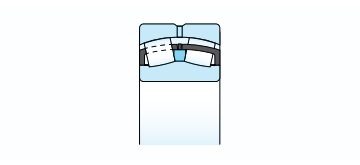

Double-row spherical roller bearings are designed with a grove and three lubrication holes on the outer ring (W33) for delivering lubricant directly to the bearing between the two rows or barrels. This helps to achieve better lubrication of bearings and consequently greater reliability in operation. Deliveries of bearings without the groove and lubrication holes need to be discussed in advance.

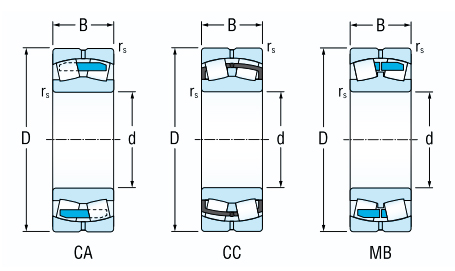

The internal structure of double-row spherical roller bearings uses symmetrical barrels with several modifications depending on the cage type.

CC the bearings have an inner ring without guide rings and with one free centre ring placed between the two rows of barrels. The guide ring is centred on the inner ring including two cages moulded from a steel band.

CA the bearings have guide rings on the inner ring. A single-piece double ridge solid brass cage is guided on the inner ring. The hole diameter in the 213 series is d ≤ 100 mm, in the 222 series the hole diameter is d ≤ 110 mm, and in the 223 series with the hole diameter d ≤ 90 mm, the cage is guided on rolling elements.

MB the bearings have guide rings on the inner ring and two double ridge solid brass cages guided on a fixed central ring.

Double-row spherical roller bearings are normally producted with the standard P0 precision class (the P0 symbol is not stated). Deliveries of bearing with greater precision need to be discussed in advance.

Commonly produced double-row spherical roller bearings have the standard radial clearance, which is not indicated. Bearings with reduced (C2) or increased (C3, C4, C5) radial play are available for special applications.

Double-row spherical roller bearings can be tilted from the central position without disrupting their correct operation as shown by the values in the following table.

| Admissible tilt | Bearing type |

|---|---|

| 1°30´ | 222XX, 230XX, 231XX, 233XX, 239XX |

| 2° | 223XX, 240XX |

| 2°30´ | 232XX, 241XX |