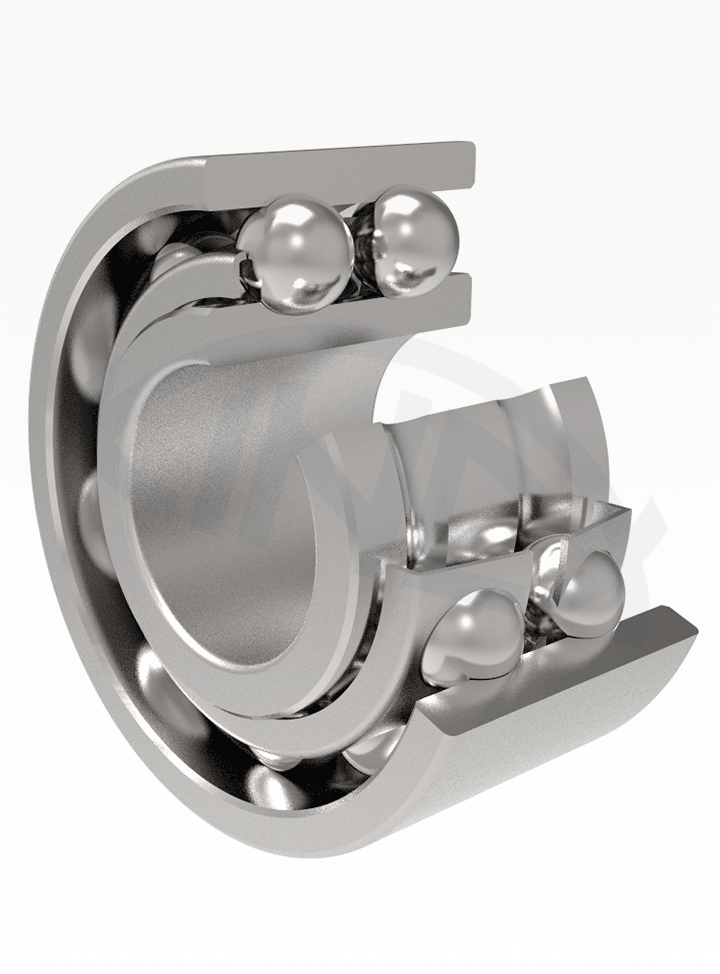

The double-row angular contact ball bearings correspond to their construction and function to a pair of single-row angular contact ball bearings turned by back to back, forming an „O“ shape. Both rings have a relatively deep raceways and they cannot be dismantled. In case of „E“ type construction, there is a filling opening on one side.

The bearings achieve high load rate due to the optimal ball size and their contact with raceways. They can effectively bear radial and axial load in both directions and they are suitable for relatively high rotation frequencies. The mounting of the "E" type construction bearings should be done in such a way, that the axial force is spread on the row of balls on the side opposite to the filling opening.

The raceways of the double row angular contact ball bearings are constructed in such way, that the flow lines of the contact points between balls and rings intersect the axis of the bearing outside the bearing itself ( contact angle α = 32°). This way the bearings can transfer the tilting point in the axial plane. Thus if there is limited space for mounting of the turning part, one bearing is sufficient.

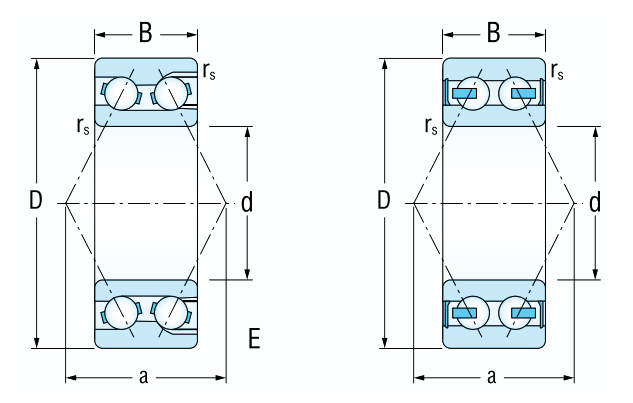

The boundary dimensions of double row angular contact ball bearings indicated in the dimension tables correspond to the international dimensional plan ISO 15.

The designation of the bearings in the basic design is indicated in the dimension tables. The difference from the basic design is designated by additional symbols according to STN 02 4608.

Double row angular contact ball bearings with covers on both sides are produced with cover sheets (2ZR), or seals (2RSR).

Bearings with covers on both sides are filled with high-quality plastic lubricant, properties of which assure lubrication throughout the whole lifetime of the bearing at normal operation conditions.

The double row angular contact ball bearings have a steel pressed cage which is marked. Steel cages are made in two designs depending on the used internal construction.

Bearings in basic design have one-piece open cage which is similar to the plastic TNGH cages. Bearings in „E“ design have one cage in S shape which is similar to the one used standard single-row ball bearings.

For special seating requirements, some bearings are produced with polyamide cages which are marked TNGH. Supply of the bearings with this cage must be negotiated in advance.

The double row angular contact ball bearings are commonly manufactured within the normal tolerance class PO (the symbol PO is not indicated). For special applications requiring a high accuracy or operating under high speed, bearings within the higher tolerance class P6 can be supplied. The limiting values of the dimensional and running accuracy deviation correspond to ISO 194

The commonly manufactured double row angular contact ball bearings have a normal axial clearance which is not indicated. For special applications, the bearings with the reduced (C2) or increased (C3, C4) axial clearance can be supplied.

For double row angular contact ball bearings mutual misalignment of bearing rings is not permissible. The misalignment of the rings causes additional load on the bearing and can shorten the endurance of the bearing.

Radial Equivalent Dynamic Load

Pr = Fr + 0,73 Fa for Fa/Fr ≤ 0,86

Pr = 0,62 Fr + 1,17 Fa for Fa/Fr > 0,86

Radial Equivalent Static Load

Por = Fr + 0,63 Fa