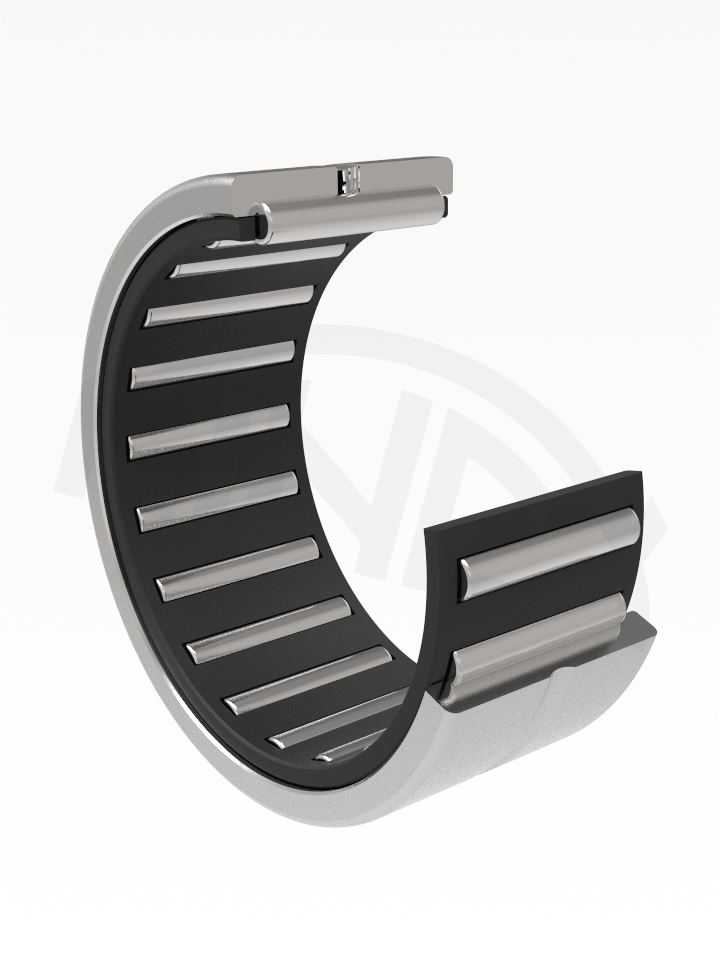

Needle bearings without inner ring and with inner ring are the roller bearings for high loading with simple spatial construction. Needle rollers guided evenly to the axis in fix cage are made with tolerance diameter of 2 µm. Outer ring with ribs and a cage with needle rollers create the construction unit.

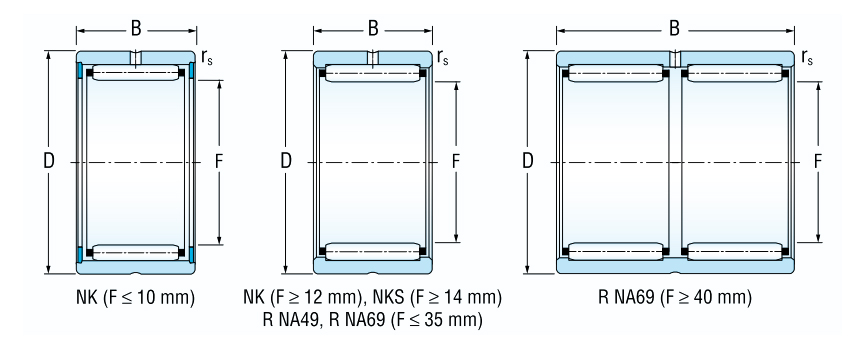

Needle bearings with ribs without inner ring are supplied in following design: NK, NKS, RNA 49, RNA 69

Needle bearings without inner ring allow optimal solution of the placing problem, whereby the raceway on the shaft may be hardened or grinded. Compared to the bearings with inner ring, it is possible to produce reinforced shafts and enhance the operation accuracy of the bearing as the tolerance of inner ring is eliminated. The shell circle of these needle bearings when not assembled is in the tolerance field of F6. The shell circle is a inner circle made by the needle rollers when they touch to the raceway of the outer ring without clearance. For lubrication purposes the bearings have a lubrication groove and opening, this does not apply for bearings NK F ≤ 10 mm.

The boundary dimensions of needle bearings, which are given by the dimensional tables, correspond to the international dimensional plan of ISO 1206.

Designation of needle roller bearings in the basic design is stated in dimensional tables.

Needle bearings are produced in normal tolerance class P0 (P0 symbol is not marked). For special placing, demanding high precision, bearings with higher class of tolerance P6 are supplied.

Normally produced needle bearings have normal radial clearance which is not marked. Bearings with reduced (C2) or increased (C3, C4, C5) radial clearance are supplied for special placing cases. The radial clearance of needle roller bearings with inner rings corresponds to the ISO 5753-1 norm.

Needle bearings have a steel cage which is not marked. For special cases of placing some bearings are made with a polyamide cage which is marked TV. Supply of the bearings with this cage must be negotiated in advance.

In the case of needle bearings with inner rings, rings can only be tilted slightly. The admissible misalignment is up to 2´. The specific admissible misalignment depends on the internal bearing design, radial clearance during operation, and the force and torque transmitted by the bearing. The quoted value is therefore approximate.

Dynamic equivalent radial load

Pr = Fr

Static equivalent radial load

Por = Fr